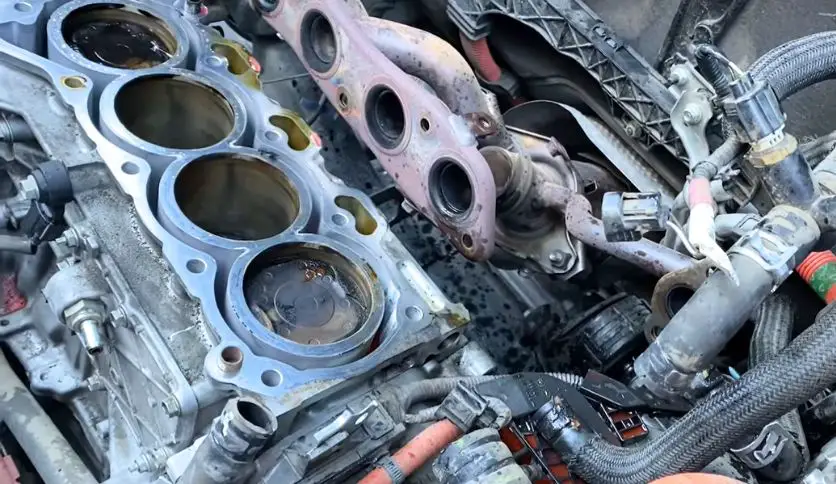

An engine can run with a broken head bolt, but it can cause significant damage and should be fixed immediately to avoid further problems. When a head bolt is broken, it compromises the cylinder head’s sealing, leading to loss of compression, coolant and oil leaks, and potential damage to the engine components.

As a result, it is essential to address the broken head bolt promptly to prevent further complications. This article will explore the consequences of running an engine with a broken head bolt and highlight the importance of timely repair for optimal performance and longevity.

Contents

Engine Run With Broken Head Bolt Challenges

Running an engine with a broken head bolt presents a significant challenge. This problem affects engine performance and can lead to further damage if not addressed promptly. Professional assistance is necessary to resolve this issue and prevent further complications.

Understanding Head Bolt Function In Engine Performance

Head bolts play a crucial role in the overall performance of an engine. These bolts secure the cylinder head to the engine block, creating a tight seal and ensuring proper compression within the combustion chamber. When a head bolt breaks, it can result in various challenges affecting engine performance.

- Loss of power or decreased engine performance

- Overheating issues

- Coolant leaks

- Excessive exhaust smoke

- Irregular engine idling

Risks of running an engine with a broken head bolt:

- Decreased fuel efficiency

- Potential damage to the engine block or cylinder head

- Inefficient combustion leads to increased emissions

- Possible engine misfires or knocking

It is essential to promptly address a broken head bolt to avoid further damage to the engine and ensure optimal performance. If you experience any symptoms of a broken head bolt, you should seek professional assistance for proper inspection and repairs.

Diagnosing A Broken Head Bolt

- Look for any visible cracks or signs of damage on the cylinder head and engine block.

- Check for coolant leaks or oil seepage around the head bolt area.

- Inspect the bolts themselves for any signs of shearing or breakage.

- Ensure proper alignment and tightness of other engine components.

- Use a borescope to inspect hard-to-reach areas of the engine.

- Perform a pressure test to identify any leaks in the cooling system.

- Use a torque wrench to measure the tightness of the head bolts.

- Consult a professional mechanic or engine specialist for a thorough inspection.

- Consider a diagnostic scan to identify any fault codes related to the head bolt issue.

- Seek advice from a trusted automotive forum or community for additional guidance.

Keeping Your Engine Running Strong With Head Bolt Issues

Engine performance can be significantly affected by head bolt issues, but there are short-term measures that can help keep your engine running strong. One important step is to select the right sealants and additives. These products can help seal gaps or leaks caused by broken head bolts, preventing further damage and ensuring optimal engine performance.

In addition to using sealants and additives, it is crucial to maintain proper coolant levels. Coolant helps regulate the temperature inside the engine and prevents it from overheating. Low coolant levels can lead to engine overheating, worsening head bolt issues, and additional strain on the machine.

By taking these short-term measures, you can manage engine performance and minimize the impact of head bolt issues. Remember to consult a professional mechanic for a long-term solution to ensure the continued smooth running of your engine.

Engine Maintenance And Head Bolt Care

Regular check-ups and maintenance are crucial to prevent head bolt failure in your engine. It is important to have effective engine warming routines in place to ensure that the head bolts are not subjected to excessive stress. Choosing quality head bolts for replacements is equally important to ensure your engine’s longevity and proper functioning.

During regular check-ups, inspect the head bolts for any signs of wear or damage, such as corrosion or elongation. If any issues are detected, it is imperative to replace the head bolts promptly with high-quality replacements. It is recommended to consult with a professional mechanic or follow the manufacturer’s guidelines for selecting the right head bolts for your specific engine model.

Regularly inspecting and maintaining the head bolts can mitigate the risk of engine failure and avoid costly repairs. Remember, proper maintenance and care of the head bolts are essential for your engine’s overall performance and longevity.

Engine issues can be a daunting challenge for any car owner to tackle. One common problem that may arise is a broken head bolt, which can cause major damage if not addressed promptly. Fortunately, there is a step-by-step guide to head bolt replacement that can help you navigate through the repair process.

When faced with a broken head bolt, it is important to assess the severity of the issue. In some cases, it may be necessary to seek professional mechanic services to ensure the repair is done correctly. They have the expertise and specialized tools to handle such repairs efficiently.

Once the head bolt has been repaired or replaced, it is crucial to ensure engine integrity moving forward. Regular maintenance checks, such as inspecting the head bolts for any signs of wear or damage, can go a long way in preventing future issues. Additionally, monitoring engine coolant levels and temperature can help detect potential problems early on.

Navigating the repairs and replacements necessary for a broken head bolt can be complex. However, with the right steps and precautions, it is possible to ensure the engine’s longevity and performance.

Frequently Asked Questions For Engine Run With Broken Head Bolt

Can You Drive A Car With A Broken Head Bolt?

Yes, driving a car with a broken head bolt is possible, but it is not recommended. A broken head bolt can lead to a loss of compression, overheating, and severe engine damage. It is best to have the head bolt repaired or replaced as soon as possible by a professional mechanic.

How Do You Know If You Have A Broken Head Bolt?

There are a few common signs that indicate a broken head bolt. These include coolant leaks, overheating, loss of power, white smoke from the exhaust, and a misfiring engine. If you notice any of these symptoms, it is advisable to have your car inspected by a qualified mechanic to determine if a head bolt is broken.

What Can Cause A Head Bolt To Break?

Several factors can cause a head bolt to break, including overheating, improper torquing during installation, engine vibration, or metal fatigue over time. It is important to follow the manufacturer’s recommended torque specification and maintenance schedule to avoid head bolt failure.

If a head bolt breaks, it may indicate an underlying issue that should be addressed.

Conclusion

Running an engine with a broken head bolt can have serious consequences. It can lead to engine overheating, loss of power, and potential damage to the cylinder head. It is crucial to address this issue promptly to avoid further complications and costly repairs.

Regular maintenance and inspection of your vehicle’s engine can help prevent such situations and ensure optimum performance. Take action now to keep your engine running smoothly and efficiently for years.

Hello, this is Wesley Shelton, currently working in a car restoration company for over 5 years. Before that, I was a worker at a small car repair shop. As I was a car freak from a young age and worked as a professional for over half a decade, I think I now know pretty much everything about every car and its parts. To establish my name as a professional and help others by sharing my knowledge, I’ve created this website, which I work on whenever I get free time. I hope you’ve enjoyed my informative blog!