Inspect valves for physical damage or abnormalities such as cracks or warping to determine if valves are bent. Another way is to perform a compression test to check for any inconsistencies.

As for the timing belt, visually inspect it for signs of wear, cracking, or missing teeth. You can also check the belt’s tension and verify its alignment.

Contents

- 1 How To Determine Bent Valves: Timing Belt Diagnosis

- 2 Visual Inspection Strategies

- 3 Performance Symptoms Analysis

- 4 Compression Testing Procedures

- 5 Leak-down Testing Insights

- 6 Using Advanced Diagnostic Tools

- 7 Timing Belt Maintenance Tips

- 8 Frequently Asked Questions On How To Tell If Valves Are Bent, Timing Belt

- 9 Conclusion

How To Determine Bent Valves: Timing Belt Diagnosis

How to Determine Bent Valves: Timing Belt Diagnosis

Recognizing signs of bent valves – The most common signs include low compression in one or more cylinders, misfires, and rough idling. Furthermore, you may also notice decreased power, acceleration, and engine overheating. These symptoms can result from a timing belt failure, which can cause the valves to come into contact with the pistons, leading to bent valves. To diagnose bent valves, it is crucial to carefully inspect the timing belt for any damage or signs of wear. If the timing belt is in good condition, a compression test can be performed to check for low compression values. Pre-diagnosis checks and preparations, such as gathering the necessary tools and accessing the timing belt area, are essential before starting the diagnostic process.

Visual Inspection Strategies

When inspecting a timing belt for signs of bent valves, there are several visual inspection strategies to consider. First, visually inspect the timing belt for physical marks or signs of wear. Look for cracks, fraying, or missing teeth that may indicate a damaged belt. Ensure the belt is properly tensioned and aligned.

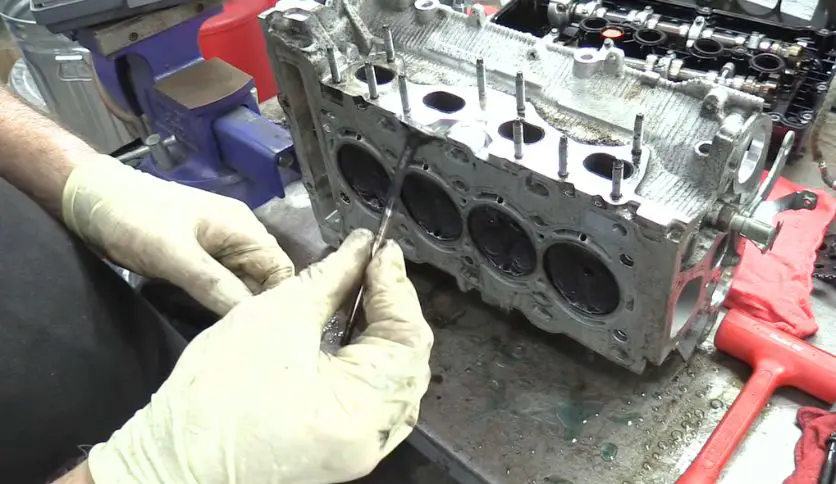

Next, check for physical signs of abnormal valve positions. Look for bent valves by observing irregular valve seating and position irregularities. Pay attention to any gaps or misalignments that may indicate valve damage.

Finally, inspect for piston and cylinder head damage. This can be done by looking for any signs of collision or impact on the piston and cylinder head. Check for visible dents, scratches, or other signs of damage that may have been caused by contact with the valves.

Performance Symptoms Analysis

When diagnosing bent valves or timing belt issues, paying attention to performance symptoms is crucial. Listening to strange engine noises can provide valuable insights. Unusual ticking or knocking sounds may indicate problems with valve timing, while a whining or squealing noise could suggest a worn timing belt. Additionally, noting performance issues during acceleration is important. If the engine lacks power or hesitates during acceleration, it could be a sign of bent valves. Assessing idling irregularities and misfires is another key factor. If the engine idles roughly or misfires, it may be due to bent valves affecting the combustion process. By being attentive to these performance symptoms and seeking professional assistance, you can determine if valves are bent or if the timing belt requires attention.

Compression Testing Procedures

Compression testing procedures can help determine whether valves are bent and whether the timing belt is functioning properly. This diagnostic test involves measuring the pressure within the combustion chamber, providing insights into the engine’s health.

A compression test is an important diagnostic tool to determine the health of an engine’s valves and timing belts. To set up a compression test, ensure the engine is warm and turned off. Remove all spark plugs and disconnect the fuel injection system. Attach a compression gauge to each cylinder and have a helper crank the engine a few times. Record the compression readings for each cylinder. To interpret the compression test results, compare the readings to the manufacturer’s specifications. If there is a significant difference in compression readings between cylinders, it may indicate bent valves or a timing belt issue. However, it’s important to acknowledge the limitations of compression testing. It can’t provide detailed information about the internal condition of the valves or the timing belt itself. Other diagnostic methods, such as a leak-down test or visual inspection, may be necessary for a comprehensive evaluation.

Leak-down Testing Insights

A leak-down test is an effective method to determine if valves are bent or if there is an issue with the timing belt. This test provides valuable insights into the overall health of an engine. Conducting a leak-down test involves several steps that help in diagnosing potential problems. The spark plugs are removed, and the piston is positioned at the Top Dead Center. Then, compressed air is introduced into the cylinder while the valves remain closed. By monitoring the air pressure and listening for any leaks, it is possible to assess the condition of the valves and the piston rings. Analyzing the leak-down test findings involves understanding the percentage of leakage and pinpointing the specific cylinders affected. This information can then be used to determine the necessary repairs or adjustments required for the engine.

Using Advanced Diagnostic Tools

Using advanced diagnostic tools is crucial for determining if valves are bent or if there is a problem with the timing belt. Employing borescopes for internal examination allows mechanics to visually inspect the valves and identify any signs of damage or wear. This method provides accurate results without the need to disassemble the engine.

Understanding scanner readings and error codes is another important aspect. These diagnostic tools provide vital information about the engine’s performance, including timing or valve functionality issues. Mechanics can diagnose problems more efficiently and effectively by accurately interpreting these readings.

Reliance on professional diagnostic equipment is essential when evaluating valves’ condition and a timing belt. Technological advancements in these tools have made it easier for mechanics to identify and address issues promptly, ensuring optimal engine performance.

Timing Belt Maintenance Tips

Regular inspection is crucial for ensuring the proper functioning of your vehicle’s timing belt. Adhering to recommended inspection intervals can detect issues early on and prevent costly repairs. It is important to demonstrate proper care for your timing belt by regularly checking for signs of wear and tear, such as fraying or cracking. By addressing these issues promptly, you can prevent more severe damage to your engine, including bent valves. Timely replacements of your timing belt are also vital to maintaining its integrity. Following the manufacturer’s guidelines for timing belt replacement is essential to keep your engine running smoothly. Doing so can avoid the risk of bent valves and other related issues, ensuring your vehicle’s reliable and efficient performance.

Frequently Asked Questions On How To Tell If Valves Are Bent, Timing Belt

How Can I Tell If My Valves Are Bent?

You can tell if your valves are bent by checking for symptoms such as misfires, loss of power, and unusual engine noises. You can also perform a compression test to determine if the valves are sealing properly.

What Causes Bent Valves In An Engine?

A timing belt or timing chain failure often causes bent valves. When the timing belt or chain breaks, the valves can collide with the pistons, causing them to bend.

Why Is A Timing Belt Important In An Engine?

The timing belt is an essential component in an engine as it synchronizes the crankshaft and camshaft rotation. This ensures that the valves open and close at the correct time, allowing the engine to run smoothly and efficiently.

Conclusion

To sum up, determining whether valves are bent in your timing belt is crucial for maintaining the performance of your vehicle’s engine. You can identify potential issues early by paying attention to warning signs such as low power, strange noises, or poor fuel efficiency.

Regular inspections by a qualified mechanic can help you catch any problems before they cause significant damage. By taking proactive measures and promptly addressing valve and timing belt issues, you can ensure your vehicle’s longevity and smooth operation.

Hello, this is Wesley Shelton, currently working in a car restoration company for over 5 years. Before that, I was a worker at a small car repair shop. As I was a car freak from a young age and worked as a professional for over half a decade, I think I now know pretty much everything about every car and its parts. To establish my name as a professional and help others by sharing my knowledge, I’ve created this website, which I work on whenever I get free time. I hope you’ve enjoyed my informative blog!